1.High yield per unit area

2.Drum body adopts a conical flow runner process to increase flow rate of filtrate.

3.Flat valve adopts multi-point fixing technology, vacuum degree is stable, and feeding concentration is high.

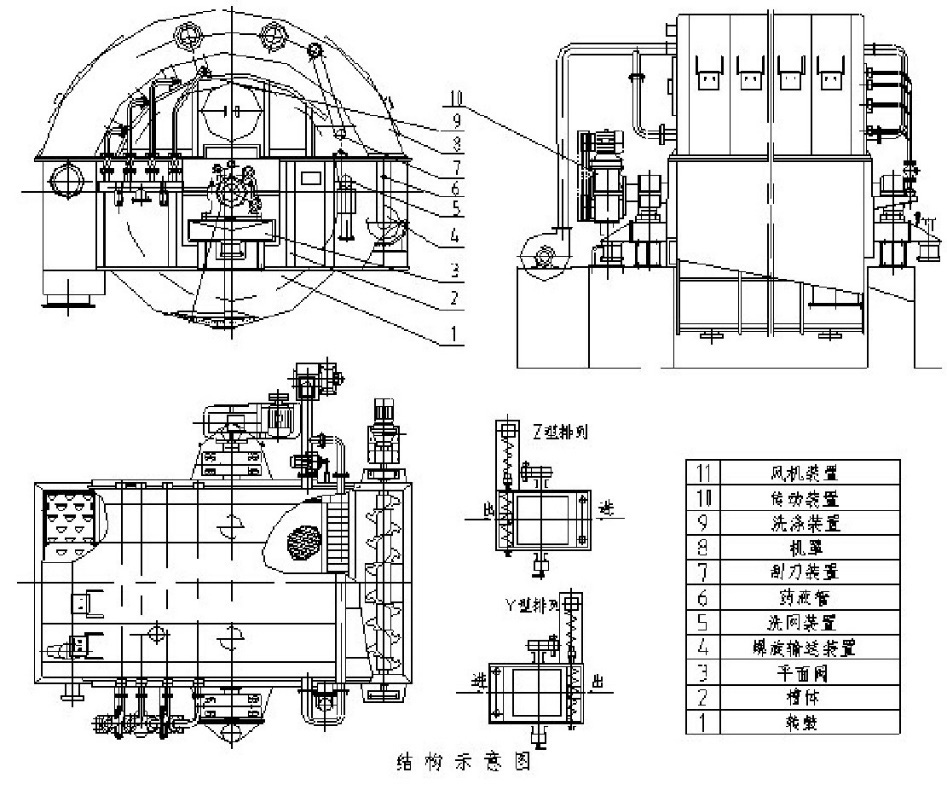

Vacuum washser also be called drum vacuum washer (group),Paper vacuum drum washer,vacuum pulp washer,Vacuum Filter Washer etc.It is a new type of flat valve washer. Every time the drum rotates, the pulp washing machine completes three processes of pulp filtration, washing, and stripping. It is widely used in the extraction and bleaching sections of various pulp materials in pulp and paper enterprises.Suitable for extracting black liquor from cooking pulp and concentrating pulp after bleaching

1.High yield per unit area

2.Drum body adopts a conical flow runner process to increase flow rate of filtrate.

3.Flat valve adopts multi-point fixing technology, vacuum degree is stable, and feeding concentration is high.

4.Flat distribution valve occupies less space, with compact structure and easy to maintain.

5.Corrugated plate can increase effective filtration area and prevent backflow and blockage.

6.Dispersion type material pressing mixing technology facilitates pulp mixing and washing effect improving. Compound side plate, liquor slice, and split sealing technology.

7.Stable operation and easy maintenance.

8.Transmission speed is adjustable and power consumption can be reduced.

|

Model/ Specification |

Drum length (mm) |

Drum Rotary Speed (rpm) |

Feed Concentration (%) |

Discharge Concentration (%) |

Black Liquor Extraction (t/d) |

Bleaching Section(t/d) |

||||

|

straw |

Bamboo pulp |

Wood pulp |

straw |

Bamboo pulp |

Wood pulp |

|||||

|

ZNK35 |

3200 |

0.8~3 |

1.5~2.5 |

8~12 |

52~70 |

70~105 |

140~210 |

70~105 |

87~122 |

175~245 |

|

ZNK40 |

3650 |

0.8~3 |

1.5~2.5 |

8~12 |

60~80 |

80~120 |

160~240 |

80~120 |

100~140 |

200~280 |

|

ZNK45 |

4100 |

0.8~3 |

1.5~2.5 |

8~12 |

67~90 |

90~135 |

180~270 |

90~135 |

112~157 |

225~315 |

|

ZNK50 |

4550 |

0.8~3 |

1.5~2.5 |

8~12 |

75~100 |

100~150 |

200~300 |

100~150 |

125~175 |

250~350 |

|

ZNK55 |

5000 |

0.8~3 |

1.5~2.5 |

8~12 |

82~110 |

110~165 |

220~330 |

110~165 |

137~192 |

275~385 |

|

ZNK60 |

5450 |

0.8~3 |

1.5~2.5 |

8~12 |

90~120 |

120~180 |

240~360 |

120~180 |

150~210 |

300~420 |

|

ZNK65 |

5200 |

0.8~3 |

1.5~2.5 |

8~12 |

97~130 |

130~195 |

260~390 |

130~195 |

162~227 |

325~455 |

|

ZNK70 |

5600 |

0.8~3 |

1.5~2.5 |

8~12 |

105~140 |

140~210 |

280~420 |

140~210 |

175~245 |

350~490 |

|

ZNK75 |

6000 |

0.8~3 |

1.5~2.5 |

8~12 |

112~150 |

150~225 |

300~450 |

150~225 |

187~262 |

375~525 |

|

ZNK80 |

6400 |

0.8~3 |

1.5~2.5 |

8~12 |

120~160 |

160~180 |

320~480 |

160~240 |

200~280 |

400~560 |

|

ZNK85 |

6800 |

0.8~3 |

1.5~2.5 |

8~12 |

127~170 |

170~255 |

340~510 |

170~255 |

212~297 |

425~595 |

|

ZNK90 |

7200 |

0.8~3 |

1.5~2.5 |

8~12 |

135~180 |

180~270 |

360~540 |

180~270 |

225~315 |

450~630 |

|

ZNK95 |

7600 |

0.8~3 |

1.5~2.5 |

8~12 |

142~190 |

190~285 |

380~570 |

190~285 |

237~332 |

475~665 |

|

ZNK100 |

8000 |

0.8~3 |

1.5~2.5 |

8~12 |

150~200 |

200~300 |

400~600 |

200~300 |

250~350 |

500~700 |

|

ZNK105 |

7450 |

0.8~3 |

1.5~2.5 |

8~12 |

157~210 |

210~315 |

420~630 |

210~315 |

262~367 |

525~735 |

|

ZNK110 |

7800 |

0.8~3 |

1.5~2.5 |

8~12 |

165~220 |

220~330 |

440~660 |

220~330 |

275~385 |

550~770 |

|

ZNK115 |

8150 |

0.8~3 |

1.5~2.5 |

8~12 |

172~230 |

230~345 |

460~690 |

230~345 |

287~402 |

575~805 |

|

ZNK120 |

8500 |

0.8~3 |

1.5~2.5 |

8~12 |

180~240 |

240~360 |

480~720 |

240~360 |

300~420 |

600~840 |