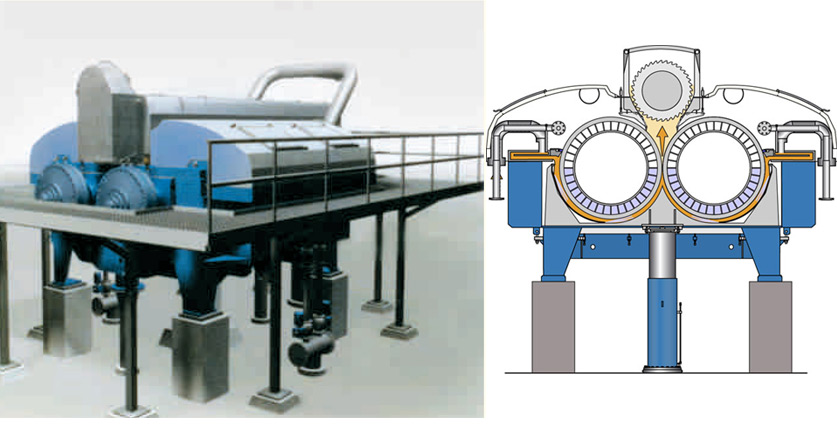

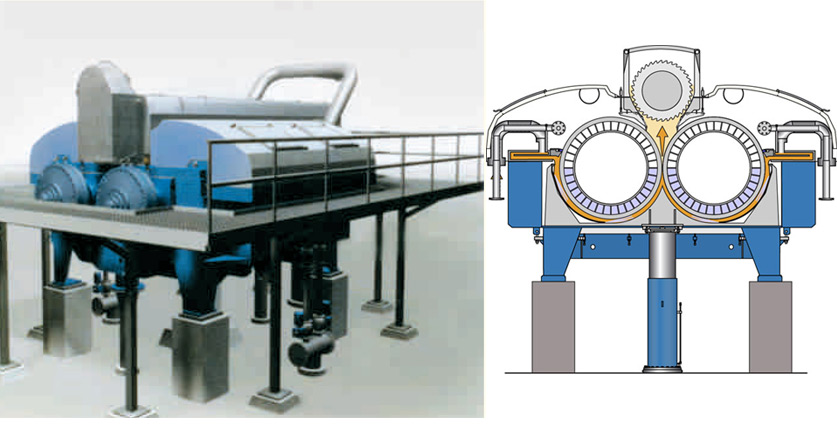

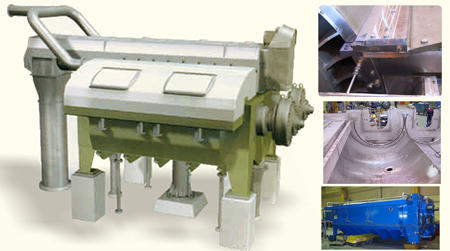

The twin roll press uses the principle of pressing to complete the entire working process. The pulp is pumped into the cow shaped dewatering area composed of the squeezing roller and the tank of thetwin roll press. Due to the pressure formed by the pulp, it is filtered and dehydrated through a porous roller filter plate, and discharged through the openings at both ends of the roller, forming a continuous slurry layer on the roller surface.

The twin roll press uses the principle of pressing to complete the entire working process. The pulp is pumped into the cow shaped dewatering area composed of the squeezing roller and the tank of thetwin roll press. Due to the pressure formed by the pulp, it is filtered and dehydrated through a porous roller filter plate, and discharged through the openings at both ends of the roller, forming a continuous slurry layer on the roller surface.

1.Adopt international advanced hydraulic drive system, pulp distribution system and washing system.

2.Be equipped with washing equipment, dehydration equipment and Replacement equipment.

3.A fully improved pulp feeding structure for better proportioning, possess independent intellectual property.

4.A new sealing and scraping mechanism that seals well during operation and is easy to control.

5.Larger filter area, stronger replacement function and better pulp washing effect

6.Advanced hydraulic drive system for more stable and reliable operation.

7.High automation for easier operation.

|

Model/ Specification |

Roll Length (mm) |

Roll Diameter (mm) |

Roll Speed (rpm) |

Inlet Concentration(%) |

Outlet Concen-tration |

Production Capacity |

||

|

Straw/ Bagasse Pulp |

Bamboo Pulp |

Wood Pulp |

||||||

|

SJ712 |

1200 |

700 |

2~20 |

3.5~10 |

20~35 |

30~40 |

60~80 |

80`100 |

|

SJ915 |

1500 |

900 |

2~15 |

3.5~10 |

20~35 |

40~60 |

85~120 |

130~160 |

|

SJ920 |

2000 |

900 |

2~15 |

3.5~10 |

20~35 |

55~85 |

125~160 |

175~210 |

|

SJ928 |

2820 |

900 |

2~15 |

3.5~10 |

20~35 |

80~120 |

165~220 |

250~300 |

|

SJ935 |

3500 |

900 |

2~15 |

3.5~10 |

20~35 |

110~150 |

225~280 |

310~370 |

|

SJ940 |

4000 |

900 |

2~15 |

3.5~10 |

20~35 |

120~170 |

220~310 |

350~400 |

|

SJ945 |

4500 |

900 |

2~15 |

3.5~10 |

20~35 |

160~180 |

285~350 |

400~480 |

|

SJ1532 |

3200 |

1500 |

2~15 |

3.5~10 |

20~35 |

220~350 |

450·600 |

700~800 |

|

SJ1540 |

4000 |

1500 |

2~15 |

3.5~10 |

20~35 |

400~550 |

800~1000 |

1200~1500 |

|

SJ1550 |

5000 |

1500 |

2~15 |

3.5~10 |

20~35 |

500~650 |

1000~1300 |

1700~1800 |

|

SJ1572 |

7200 |

1500 |

2~15 |

3.5~10 |

20~35 |

750~1000 |

1500~1800 |

1500~3000 |