The process can be also used to produce the dissolving pulp depending on different raw materials.

Based on traditional cooking characteristics, our company developed super batch cooking process with an annual output of 300,000 tons in 2007. It can save about 60% of the cooking steam consumption, which is equivalent to reducing the coal consumption by 10.000 tons per year (Calculated in standard coal). At the same time,we are able to decrease the emissions of sulfur dioxide and soot from the alkali recovery boiler by approximately 15%, reach zero discharge of wastewater and reduce the discharge of bleaching wastewater.

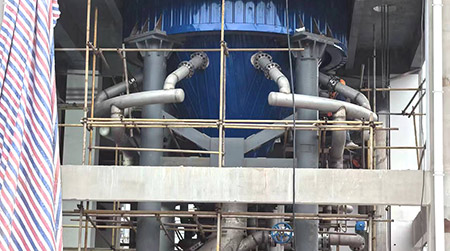

Anyang Machinery adheres to market demand orientation, combines the company's nearly 40 years of experience in super batch cooking, introduces high-end pulp making technology experts, and combines the advantages of domestic and foreign displacement cooking to develop a displacement cooking system technology package with independent intellectual property rights and an annual output of 300000 tons of pulp making and dissolved pulp. It plans to achieve general contracting service for the pulp making process and equipment.

The cooking section basically adopts the sulfate pulping process, using low energy consumption, batch displacement cooking process and equipment, namely: SuperBatchTM cooking system, RDH cooking system or DDSTM cooking system.Cooking methods: conventional cooking and displacement cooking.

According to the different raw materials, this process can also produce dissolved pulp.

Based on traditional cooking characteristics, our company developed one super batch cooking process with an annual output of 300000 tons in 2007. Super batch cooking process is an efficient and energy-saving pulp production process developed through energy conservation and emission reduction on the basis of traditional cooking process. Compared with traditional batch cooking process, it can save about 60% of cooking gas consumption, which is equivalent to reducing 10000 tons of coal consumption per year (standard coal quantity). Meanwhile, we can reduce sulfur dioxide and coal smoke emissions from alkali recovery boilers by approximately 15%, achieve zero wastewater discharge, and reduce bleach water emissions

A: As producing one ton of pulp, traditional equipment needs about 2 tons-2.5 tons of steam consumption. Compared with it, the batch cooking process equipment can reduce the consumption greatly down to 0.6 ton-0.8 ton.

B: Pulp lignin Removing, low Kappa value and high strength of paper.

C: High-quality of pulp bleaching, due to low kappa value, high strength, etc., oxygen delignification, good production environment, at the same time, chemicals drop in usage gradually so as to lower the pollution and papermaking costs.

D: The whole production process adopts automatic control. The system reliability is improved greatly, and the pulp quality is stable and reliable.

Super batch cooking is a new pulping technology developed on the basis of RDH cooking system. Super batch cooking adheres to the advantages of RDH and improves several technical issues in the RDH process. One of them is that the system has a strong and stable tank area, which is achieved by adding special partitions in the hot and warm black liquid tank. The other is advanced control technology, such as simulated predictive control (MPC), multivariable control, etc., which reduces the impact on cooking operations.

The super batch cooking operation process includes several steps, including loading, primary cooking, middle cooking, final cooking (heating/insulation), recovery, and digester placement.

Digester: 50m',75m',110m',135m',175m’,225m’,250m',330m’and 400m' . According to different processes, main manufacturing materials are carbon steel, stainless steel. composite board and duplex stainless steel.

Blow Tank: 80m’,150m³,225m’,330m³,500m³,1050m³ and 1800m³ . According to different processes, main manufacturing materials are carbon steel, stainless steel, composite board and duplex stainless steel.

Vacuum Washer: 30m² ,45m²,60m²,80m²,100m²and 120m² . According to different technologies, main manufacturing materials are carbon steel and stainless steel.

Replacement Tank: hot black liquor tank, hot white liquor tank, warm black liquor tank,cold black liquor tank, various heat exchangers. According to different requirements,main manufacturing materials are carbon steel, stainless steel and duplex stainless steel.

|

Model |

ZJG1 |

ZJG2 |

ZJG3 |

ZJG4 |

ZJG5 |

ZJG6 |

|

|

Effective Volume (m3) |

50 |

75 |

110 |

135 |

175 |

225 |

|

|

Internal Diameter(mm) |

Φ3000 |

Φ3250 |

Φ3600 |

Φ3600 |

Φ4500 |

Φ4500 |

|

|

Max. Working Pressure (Mpa) |

0.8 |

||||||

|

Max. Working Temperature (℃) |

175 |

||||||

|

|

Corollary Equipment |

||||||

|

Alkaline Solution Heater |

Model |

ZJG1-2 |

ZJG2-2 |

ZJG3-2 |

ZJG4-2 |

ZJG5-2 |

ZJG6-2 |

|

Spec M2 |

40 |

65 |

90 |

110 |

140 |

190 |

|

|

Alkaline Solution Circulating Pump |

Model |

ZBY21 |

ZBY22 |

ZBY24 |

ZBY24 |

ZBY24 |

ZBY24 |

|

Spec |

Φ200 |

Φ250 |

Φ300 |

Φ300 |

Φ300 |

Φ300 |

|

|

Discharge Valve |

Model |

Q647Y-16P |

Q647Y-16P |

Q647Y-16P |

Q647Y-16P |

Q647Y-16P |

Q647Y-16P |

|

Spec |

Φ200 |

Φ200 |

Φ200 |

Φ200 |

Φ300 |

Φ300 |

|

|

Automatic Cover |

Φ770 |

||||||

|

Blow tank |

Model |

ZJP2 |

ZJP3 |

ZJP4 |

ZJP5 |

ZJP6 |

ZJP7 |

|

Spec M2 |

150 |

225 |

330 |

400 |

500 |

800 |

|

|

Internal Diameter(mm) |

Φ5000 |

Φ5600 |

Φ6500 |

Φ7000 |

Φ7000 |

Φ8000 |

|

|

Max. Working Pressure (Mpa) |

0.25 |

||||||

|

Max. Working Pressure (Mpa) |

175 |

||||||

|

Model |

ZJG3 |

ZJG4 |

ZJG5 |

ZGJ6 |

ZJG7 |

ZJG8 |

ZJG9 |

|

Effective Volume (m3) |

110 |

135 |

175 |

225 |

250 |

330 |

400 |

|

Internal Diameter(mm) |

3600 |

4000 |

4500 |

4500 |

4500 |

5600 |

5800 |

|

Design Pressure(Mpa) |

0.9/1.2 |

||||||

|

Design Temperature(℃) |

180/240 |

||||||

|

Complete Tank |

Cold Black Liquor Tank, Warm Black Liquor Tank, Hot Black Liquor Tank, Cold White Liquor Tank, Hot White Liquor Tank |

|

Heat Exchanger |

Warm Black Liquor Cooler,Black/White Liquor Exchanger, White Liquor Heater, Steam Distributor, Cyclone Separator |