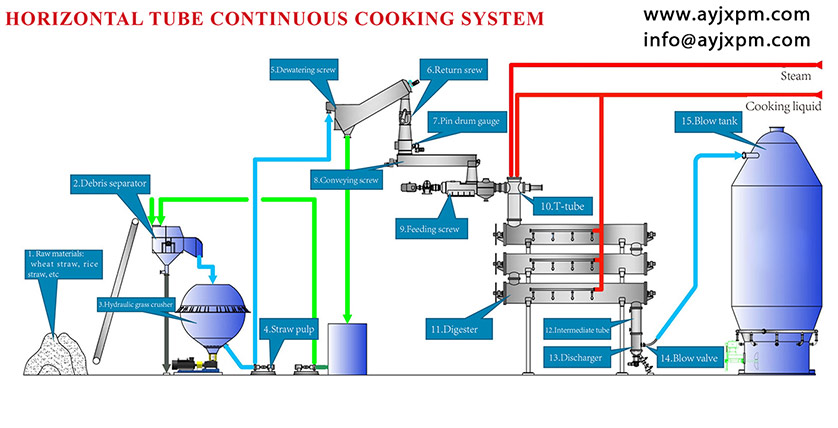

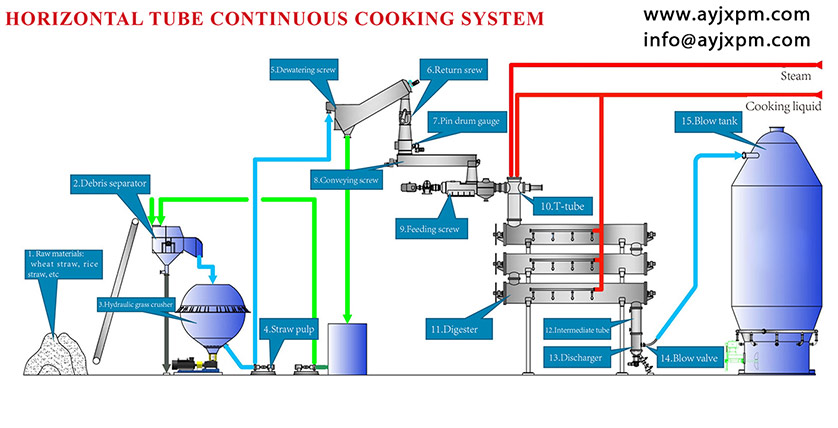

This system is suitable for the production of sulfate based chemical pulp from wheat straw, rice straw, and bagasse raw materials. It consists of a wet preparation system and a horizontal tube continuous cooking system.

This system is suitable for the production of sulfate based chemical pulp from wheat straw, rice straw, and bagasse raw materials. It consists of a wet preparation system and a horizontal tube continuous cooking system. It is designed, manufactured, and matched according to the raw materials, pulp production process, and output. It is composed of different specifications of main and auxiliary single machines. The system is equipped with advanced instruments, electrical control, and DCS control systems to ensure the various performance indicators of the equipment.

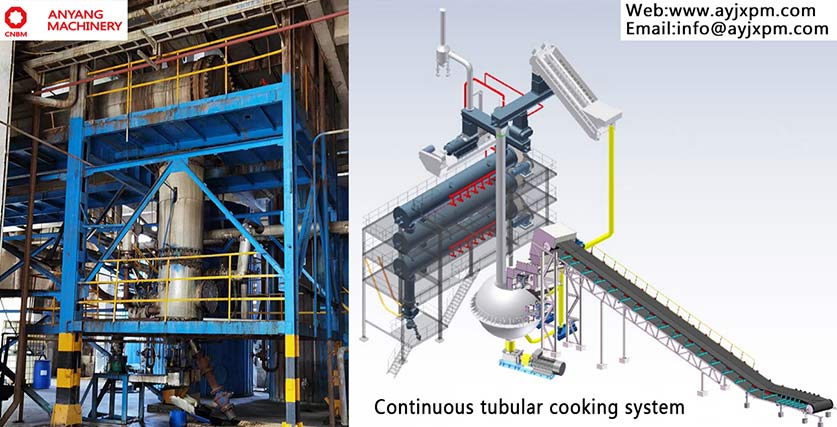

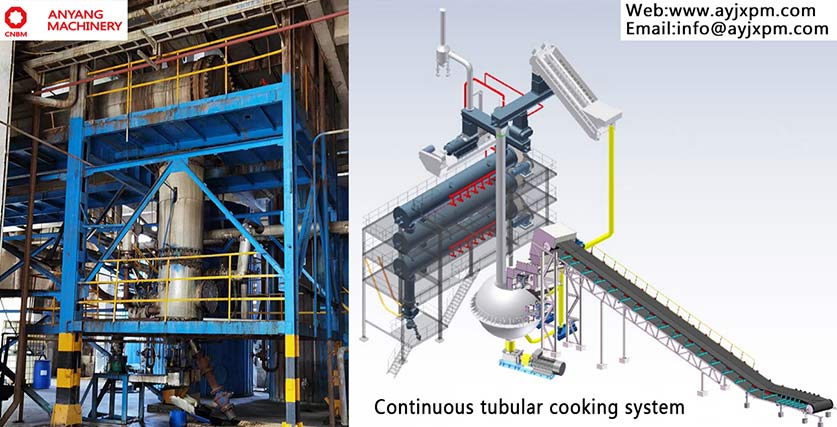

Horizontal tube continuous cooking system,Also be called Continuous tubular cooking system,Horizontal tube cooking,Super batch cooking,Horizontal tube continuous digester,Continuous tubular digester.This horizontal tube continuous cooking system and waste liquid extraction, pulp washing and purification, black liquid concentration treatment system.It used for all kinds of chemical pulp production plant, production according to customer requirements. Our scheme is configured according to the user's requirements.Our proposal including the main equipment, auxiliary equipment, automatic control system of the production line.The rest of the public works, civil engineering, installation etc. are completed by the user or our we can discuss.

The horizontal tube continuous cooking system is the main equipment for non wood fiber raw material pulping, which can be used for chemical, semi chemical, and biological pulping, as well as pre-treatment of chemical pulp and bio mechanical pulp. According to the different production capacity of the pulping system, in a horizontal tube continuous cooking device, it is usually necessary to configure one to four cooking tubes of the same specifications, and these cooking tubes are mostly composed of upper and lower series stacking methods. The fiber raw materials are first fed into the first cooking tube by a spiral feeder, and then driven and stirred by the spiral blades. They are fully mixed with the medicine during slow movement, while being heated or insulated by pressure steam introduced into the cooking tube. At a certain temperature, the material passes through each cooking tube in sequence according to the predetermined pulping reaction time of the process, until it is discharged from the outlet of the last tube, completing the impregnation and cooking process.