As the latest generation of white water recovery and pulp thickening equipment, this product can save energy, reduce water consumption and fiber loss, while protect the environment and prevent pollution.It is mainly suitable for white water recovery in paper mills, and its performance is superior and meets advanced national standards.

In the white water recovery process, the fiber recovery rate is high, water circulation is achieved,water consumption is reduced, and white water pollution is prevented.

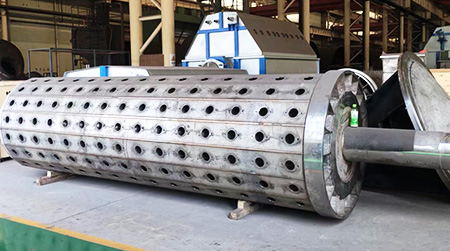

The fan-shaped plate has excellent structure with high strength, easy disassembly, large effectivefiltration area and good filtration effect.

The equipment products have complete specifications and various diameters, and filtration area can be changed according to different production requirements.

The adjustable distribution valve made of special wear-resistant material has good sealing effect.Thecomposite sealing tape can provide the maximum sealing effect.

Compact structure, small area occupied and high yield.

Good economic and social benefits.

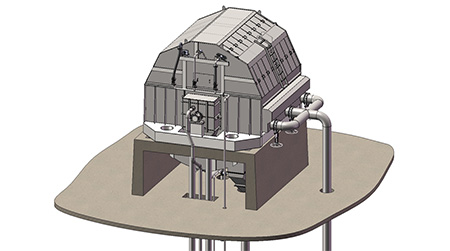

Disc Vacuum Filter Structure And Principle

The disc vacuum filter mainly consists of the following parts: tank body, main shaft, filter disc, distribution valve, etc. The tank body can accommodate materials and maintain a stable liquid level. The filter disc function is filter pulp. The distribution valve is connected to the main shaft which purpose is to achieve different functions of each partition during the filtration process.

Disc vacuum filter uses vacuum as the power for filtration, recycling fibers and fillers.

When the main shaft drives the filter disc to rotate below the liquid level, the fan-shaped plate enters the atmospheric filtration zone, and the liquid in the tank passes through the filter screen under static pressure and is discharged through the outlet of the atmospheric filtration zone of the main shaft and distribution valve.

|

Model / ltem |

ZNH25 |

ZNH35 |

ZNH45 |

ZNH55 |

|

Disc Diameter (mm) |

2500 |

3500 |

4500 |

5500 |

|

Disc Filtration Area ( m²) |

8.5 |

16.7 |

26 |

38 |

|

Processing Capacity |

0.6-3m' /m'.h(White water recovery) 0.7-1.5t/m'.d(Pulp thickened) |

|||

|

Fiber Recovery Rate(%) |

>95 |

|||

|

Filtration Clarity(mg/L ) |

20-80 |

|||

|

Inlet Concentration (%) |

0.2-0.6(White water recovery) 0.5-1.2(Pulp thickened) |

|||

|

Outlet Concentration (%) |

4-6(White water recovery) 4-15(Pulp thickened) |

|||

|

Main Material |

The part contacted with the material is made of SS304 |

|||

|

Vacuum Degree(Mpa ) |

0.02-0.06 |

|||

|

Mesh Washing Water Pressure(Mpa) |

0.7 |

|||

|

Stripping Water Pressure(Mpa ) |

0.7 |

|||

Note:Fan shaped plate without filter filtering area about 15% more than the mesh belt type fan shaped plate.

|

Disc Quantity |

ZNH25 |

ZNH35 |

ZNH45 |

ZNH55 |

|

Total Size (LxWxH) mm |

Total Size (LxWxH) mm |

Total Size (LxWxH) mm |

Total Size (LxWxH) mm |

|

|

4 |

3885*3035*4168 |

|

|

|

|

6 |

4485*3035*4168 |

|

|

|

|

8 |

5085*3035*4168 |

5397*4100*5664 |

5907*5450*6615 |

|

|

10 |

5685*3035*4168 |

5685*3035*4168 |

6507*5450*6615 |

6700*6400*7235 |

|

12 |

6285*3035*4168 |

6597*4100*5664 |

7107*5450*6615 |

7300*6400*7235 |

|

14 |

6885*3035*4168 |

7197*4100*5664 |

7807*5450*6615 |

7900*6400*7235 |

|

16 |

|

7797*4100*5664 |

8307*5450*6615 |

8500*6400*7235 |

|

18 |

|

8397*4100*5664 |

8907*5450*6615 |

9100*6400*7235 |

|

20 |

|

|

|

9700*6400*7235 |

|

22 |

|

|

|

10300*6400*7235 |

|

24 |

|

|

|

10900*6400*7235 |

Note:Shape size is for reference only, subject to actual order.

L=Length. W=Width. H=Height