AM is a fixed production company for the cooking equipments designated by the State-owned Assets Supervision and Administration Commission(SASAC).Since the 1980s, it has been dedicated to produce400,000- 500,000tons of batch cooking equipment, continuous cooking equipment and other traditional cooking equipments for paper making, and has provided the entire production lines for more than 60 paper companies.

The chemical pulp production lines AM has provided has occupied a market share of more than 90% in China. The product quality is higher, the operation is stable, and the after-sales service is thorough and satisfactory,winning customers’high favors in the market.

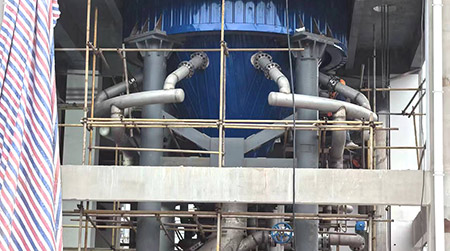

Digester is one of the leading products of our company. We can produce various products with different specifications, including 503, 75m3, 110m3, 135m3, 175m3, 225m3, 250m3, 330m3 and 400m3 of digester series. The maximum diameter is 5.8m and the maximum capacity is 400m3. Because of process difference between the alkaline pulp and the acid pulp, the digesters can be made of carbon steel, stainless steel, composite steel, or duplex stainless steel. The digester series are mainly used for chemical pulp and dissolved fiber steaming operations.

Digester is mainly used for cooking and pulpingwith wood, bamboo and the like as raw materials.The water content of the material is less than 15%, the ash content is 2%-3%, the cellulose content is 50-55%,the lignin content is 22%-25%,and the content of silicon is less than 3%. First, the material is cut into thin chip(25mmx30mm),and then it enters the digester filled with coolant and steam through the conveyor belt. The cooking time is determined by the pulping process requirements (Yield and hardness of pulp). and it will last for 5.5h-6h. The cooking temperature is 160°C-175°C.The heating process mainly involves the effective indirect heating zone of the tube heater. The liquor flowing out from the center goes through the tube to be heated and transported from top to bottom, and then it will be heated circularly for8-12 times per hour. At the same time, the steam enters through the vents at the bottom for auxiliary heating. During the cooking process, the gas is exhausted through the upper vents to reduce the false pressure caused by the air inside the main body of the digester to ensure the uniformity of the cooking pulp and improve the quality of the pulp. After the cooking is completed, the pulp is separated.

|

Model |

ZJG1 |

ZJG2 |

ZJG3 |

ZJG4 |

ZJG5 |

ZJG6 |

|

|

Effective Volume (m3) |

50 |

75 |

110 |

135 |

175 |

225 |

|

|

Internal Diameter(mm) |

Φ3000 |

Φ3250 |

Φ3600 |

Φ3600 |

Φ4500 |

Φ4500 |

|

|

Max. Working Pressure (Mpa) |

0.8 |

||||||

|

Max. Working Temperature (℃) |

175 |

||||||

|

|

Corollary Equipment |

||||||

|

Alkaline Solution Heater |

Model |

ZJG1-2 |

ZJG2-2 |

ZJG3-2 |

ZJG4-2 |

ZJG5-2 |

ZJG6-2 |

|

Spec M2 |

40 |

65 |

90 |

110 |

140 |

190 |

|

|

Alkaline Solution Circulating Pump |

Model |

ZBY21 |

ZBY22 |

ZBY24 |

ZBY24 |

ZBY24 |

ZBY24 |

|

Spec |

Φ200 |

Φ250 |

Φ300 |

Φ300 |

Φ300 |

Φ300 |

|

|

Discharge Valve |

Model |

Q647Y-16P |

Q647Y-16P |

Q647Y-16P |

Q647Y-16P |

Q647Y-16P |

Q647Y-16P |

|

Spec |

Φ200 |

Φ200 |

Φ200 |

Φ200 |

Φ300 |

Φ300 |

|

|

Automatic Cover |

Φ770 |

||||||

|

Blow tank |

Model |

ZJP2 |

ZJP3 |

ZJP4 |

ZJP5 |

ZJP6 |

ZJP7 |

|

Spec M2 |

150 |

225 |

330 |

400 |

500 |

800 |

|

|

Internal Diameter(mm) |

Φ5000 |

Φ5600 |

Φ6500 |

Φ7000 |

Φ7000 |

Φ8000 |

|

|

Max. Working Pressure (Mpa) |

0.25 |

||||||

|

Max. Working Pressure (Mpa) |

175 |

||||||

|

Model |

ZJG3 |

ZJG4 |

ZJG5 |

ZGJ6 |

ZJG7 |

ZJG8 |

ZJG9 |

|

Effective Volume (m3) |

110 |

135 |

175 |

225 |

250 |

330 |

400 |

|

Internal Diameter(mm) |

3600 |

4000 |

4500 |

4500 |

4500 |

5600 |

5800 |

|

Design Pressure(Mpa) |

0.9/1.2 |

||||||

|

Design Temperature(℃) |

180/240 |

||||||