Crusher is a machine used for coarse crushing. It is generally used to process unprocessed raw materials or leftovers to make them smaller in size for easy recycling. Compared with other crushers, their rotors has features of low speed, low noise and low energy consumption.

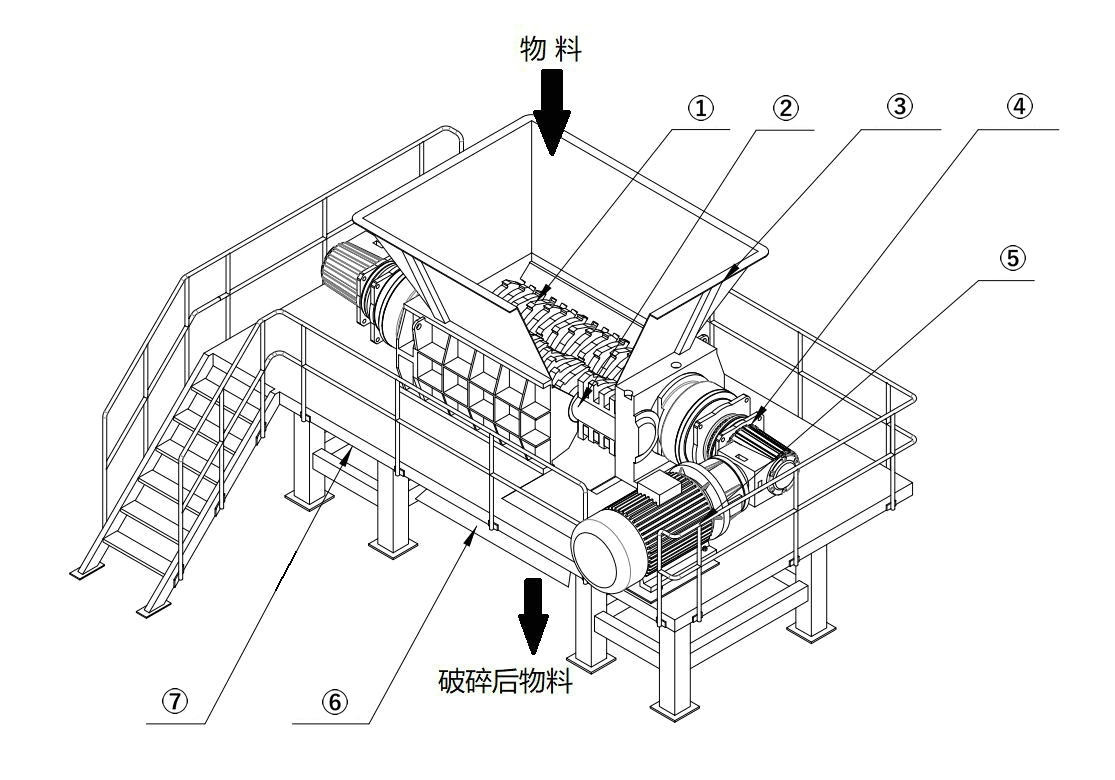

The Crusher is composed of frame, knife box, motor, gearbox, hopper and so on. It adopts "double motors + double planetary gearboxes", which has strong power and high operation stability. It is used in environmental protection fields such as biomass waste crushing, bulky waste disposal, resource regeneration, and solid waste pretreatment. The equipment has the characteristics of low speed and high torque, and has the advantages of large shearing force, good shredding effect, low noise and good stability.

1.Shred off-spec products into smaller pieces for recycling.

2.Reduce the volume of unprocessed raw materials so that they can be mixed with other materials.

3.Shred organic matter to make biofuel. Such as: waste woven bags, wood, household garbage.

4.Shred some waste plastic materials for reuse, such as shredding of tires.

5.Shred industrial waste for sorting and recycling.

6.Shred scrap metal, furniture, appliances for recycling.

1.blade,2.shaft,3.feeding hopper,4.gearbox,5.motor,6.discharging hopper,7.frame

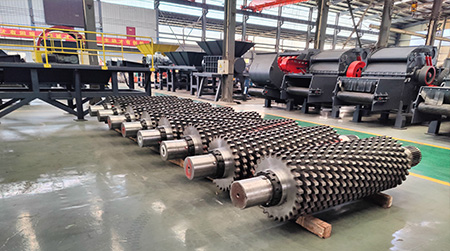

The chassis structure is composed of bearing box, side blade, box body, large shaft, moving blade, spacer, bearing, bearing cover, reducer bell-shaped support and corresponding sealing structure.

The crushing principle of the Crusher is that the two rotors are equipped with staggered blades, and the two rotors rotate in opposite directions to achieve crushing through the shearing of the knife blades, and the tearing of the knife teeth. The main shearing method is the shearing action of the adjacent moving knife blade, and the secondary shearing method is the tearing action of the moving knife teeth.