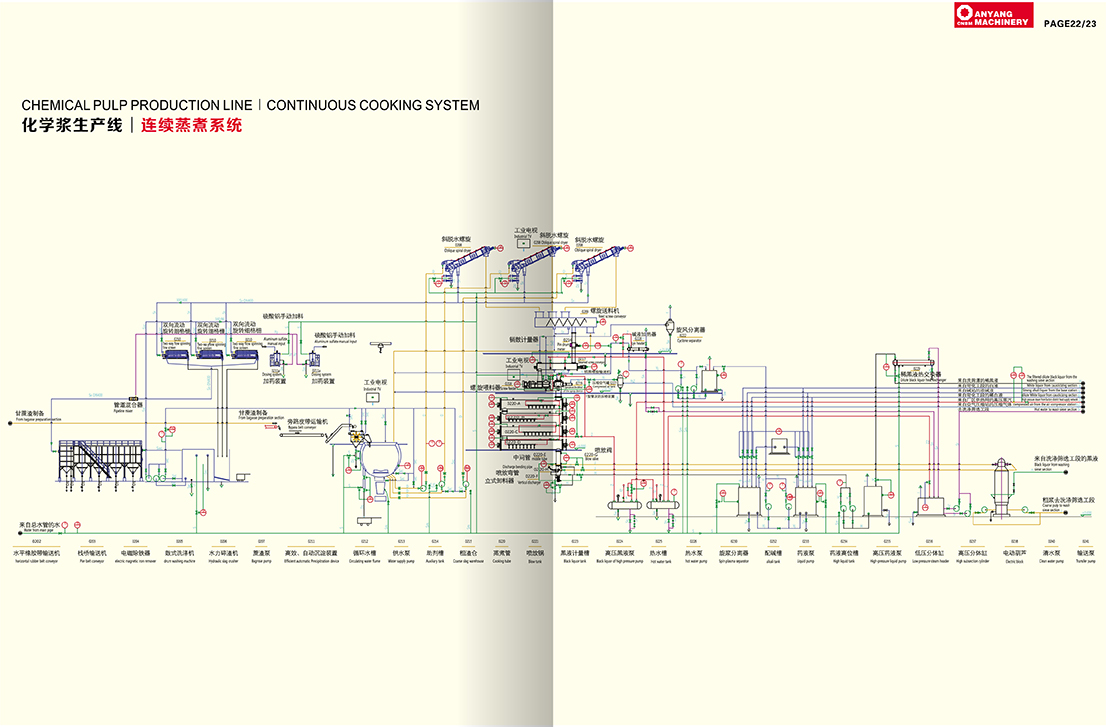

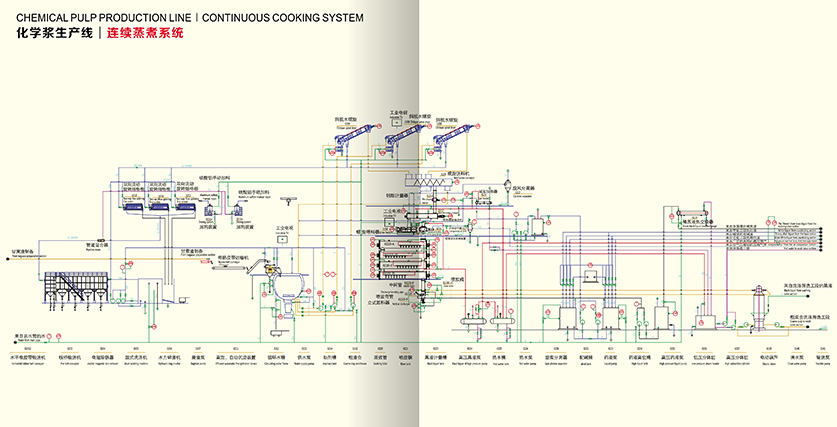

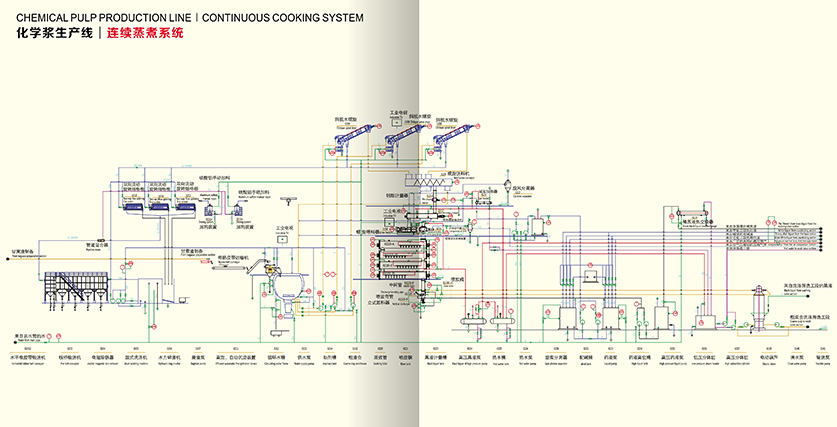

Continuous cooking process includes the entire continuous process from feeding to discharging. It is mainly used for the alkaline pulping, nitrite cooking and prehydrolysis sulfate and sulfite cooking. Now it is developed and used for the pulping of various raw materials, including wood chips and loose permeable non-wood fiber materials,such as bagasse, reed, wheat straw and so on.

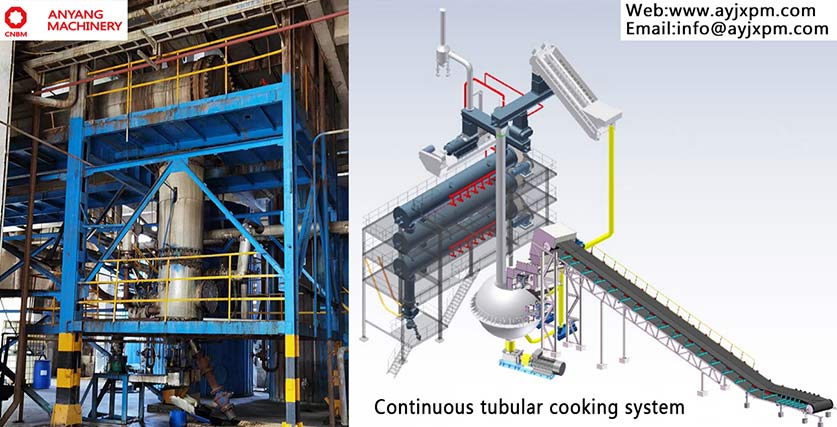

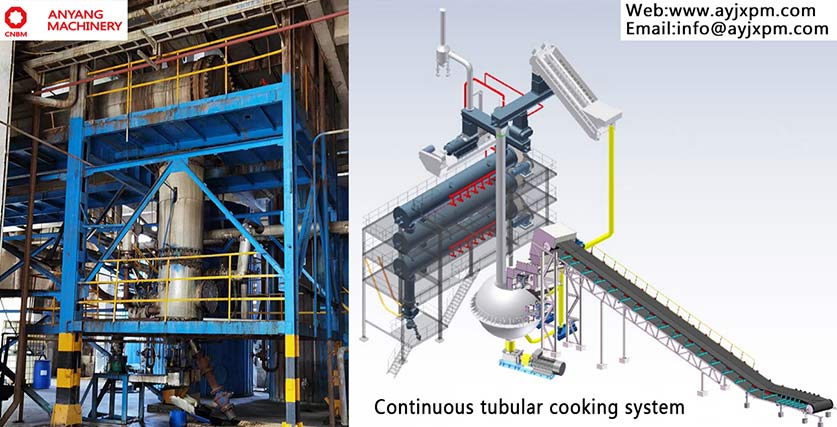

The horizontal tube continuous cooking system is the main equipment for non wood fiber raw material pulping, which can be used for chemical, semi chemical, and biological pulping, as well as pre-treatment of chemical pulp and bio mechanical pulp. According to the different production capacity of the pulping system, in a horizontal tube continuous cooking device, it is usually necessary to configure one to four cooking tubes of the same specifications, and these cooking tubes are mostly composed of upper and lower series stacking methods. The fiber raw materials are first fed into the first cooking tube by a spiral feeder, and then driven and stirred by the spiral blades. They are fully mixed with the medicine during slow movement, while being heated or insulated by pressure steam introduced into the cooking tube. At a certain temperature, the material passes through each cooking tube in sequence according to the predetermined pulping reaction time of the process, until it is discharged from the outlet of the last tube, completing the impregnation and cooking process.

1.Low energy consumption, low steam and electricity consumption, and no peak load.

2.High pulp yield and small area occupied.

3. Low per unit chemical consumption.

4. More cooking uniformity and less slag.

5. High automation and low labor intensity.