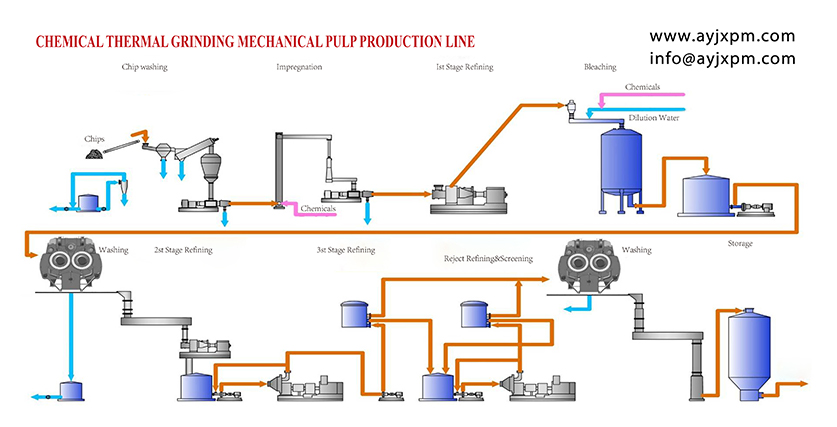

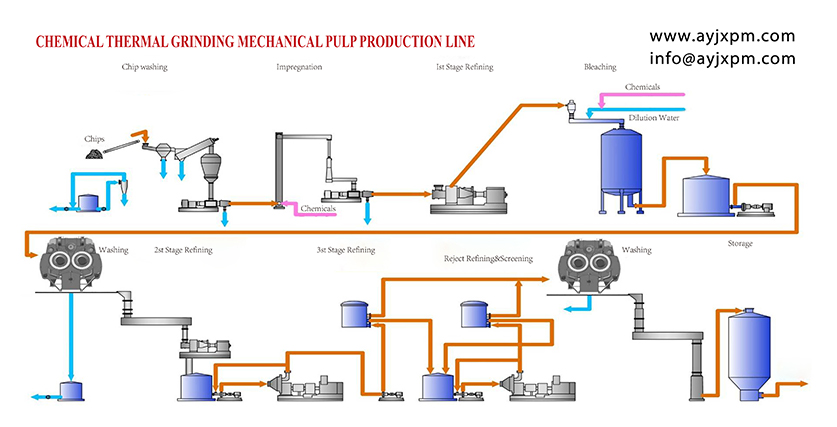

The bleaching chemical thermal mechanical pulp system starts from the washing of wood chips and ends at the pulp storage tower. It consists of the following parts: wood chip washing, steaming,impregnation, high concentration grinding, Washing before bleaching, bleaching, Washing after bleaching, low concentration grinding, screening and pulp residue regrinding ,concentration and storage.

The bleaching chemical thermal mechanical pulp system starts from the washing of wood chips and ends at the pulp storage tower. It consists of the following parts: wood chip washing, steaming,impregnation, high concentration grinding, Washing before bleaching, bleaching, Washing after bleaching, low concentration grinding, screening and pulp residue regrinding ,concentration and storage.

1. CTMP is a high yield pulp type, with a yield of over 90%, which is about twice that of chemical pulp. Chemical pulp ranges from 44% to 48%, so the wood consumption per ton of chemical pulp production is twice that of CTMP. As is well known, pulp and paper production is a major user of raw materials, with an annual consumption of around 600 million meters worldwide. One out of every ten trees harvested is used for static pulp and paper production. Currently, except for a few countries, there is a contradiction between the development of the paper industry and forest resources and environmental protection. Vigorously developing high yield pulp varieties, minimizing paper weight, and fully utilizing waste paper for reuse have become the joint efforts of pulp and paper workers. The forest coverage rate of t4% in China belongs to countries with poor forest resources, so it is imperative to vigorously develop CTMP

(1) High water absorption rate of paper pages

(2) Strong water retention ability of paper pages

(3) Good strength for wet, dry, and cushioning

(4) High whiteness and cleanliness.

(5) Paper is soft and has a good hand feel