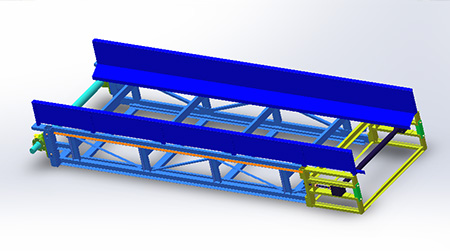

BFW series chain conveyor is mainly used to convey various kinds of waste paper in bulk or in bundle which can be horizontal conveyor or inclined conveyor(<25°). It is mainly used for feeding waste paper to pulper.

BFW series chain conveyor is mainly used to convey various kinds of waste paper in bulk or in bundle which can be horizontal conveyor or inclined conveyor(<25°). It is mainly used for feeding waste paper to pulper.

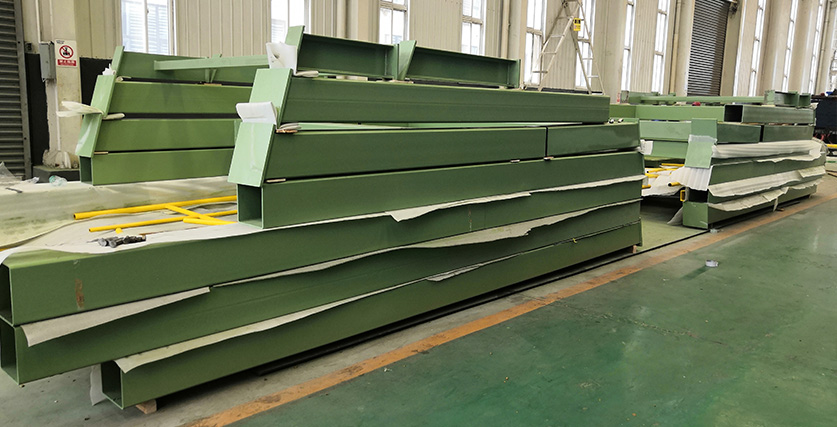

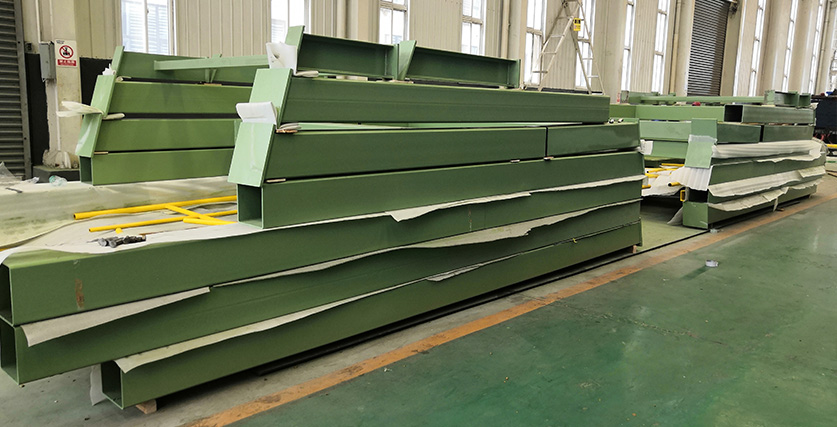

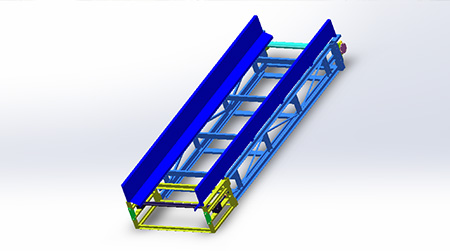

It adopts chain to drive through plate to transport raw material. With advantages of reasonable structure, large transmission capacity, lower power consumption, less wear, reliable operation, it is the ideal waste paper conveying equipment.

|

Model / Project |

BFW |

|||||||

|

Chain plate effective width: mm |

1200 |

1400 |

1600 |

1800 |

2000 |

2200 |

2400 |

|

|

Feeding capacity: m3/h |

65-210 |

80-255 |

95-300 |

110-345 |

140-390 |

160-430 |

200-500 |

|

|

Feeding speed: m/min |

0-8 |

|||||||

|

Convey angle: ° |

<25 |

|||||||

|

Conveying length :m |

<35 |

|||||||

|

Convey material: |

Pulp board, waste paper in bundle or in bulk |

|||||||

|

Maximum width of raw Material: mm |

1000 |

1200 |

1400 |

1600 |

1800 |

2000 |

2200 |

|

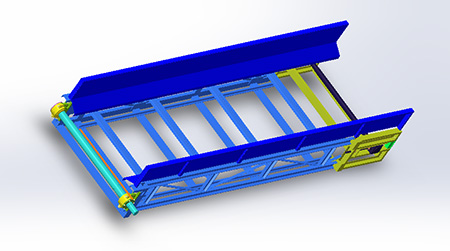

Chain conveyor consists of five parts: head drive device, tail device, tension device, chain plate and rack.

To meet the needs of the users, and consider the technical layout requirements, transmission installation of the chain conveyor can be divided into left and right types, (look up along the material running direction, transmission installation in the right of the machine is the right type, whereas for left type)

TUsers can chose the chain conveyor installation type according to the technical design requirement. And the left or right type should be indicated in the contract when customer places an order.