Fixed belt conveyor is continuous handling unit which transports the load with cotton duck, nylon polyester duck and steel wire covered belt, which can be widely used in coal, metallurgy...

Fixed belt conveyor is continuous handling unit which transports the load with cotton duck, nylon polyester duck and steel wire covered belt, which can be widely used in coal, metallurgy, chemical industry, light industry, petroleum, port, mechanical etc to convey all kinds of bulk materials and the piece.

|

Belt width(mm) |

Percent of big lump material (weight percentage) |

|||

|

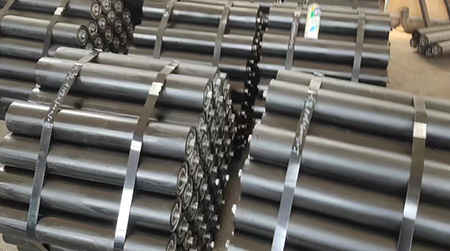

10 |

20 |

50 |

100 |

|

|

500 |

140~90 |

130~80 |

120~70 |

100~50 |

|

650 |

210~110 |

190~100 |

160~90 |

120~65 |

|

800 |

270~130 |

250~120 |

220~110 |

150~80 |

|

1000 |

340~160 |

300~150 |

260~140 |

180~100 |

|

1200 |

390~200 |

350~190 |

300~170 |

220~130 |

|

1400 |

450~230 |

400~220 |

340~200 |

260~150 |

|

1600 |

500~260 |

450~240 |

380~220 |

290~180 |

|

1800 |

550~290 |

480~270 |

420~240 |

320~200 |

|

2000 |

580~320 |

500~300 |

450~260 |

350~230 |

|

2200 |

600~350 |

520~320 |

480~290 |

380~260 |

|

≥2400 |

620~380 |

550~360 |

500~330 |

410~280 |

Notes:1.If the move angle of the material is 20°, choose the max parameter. If the move angle is 30°,choose the min parameter.2. The max granular size should no more than 350mm when conveying hard material.

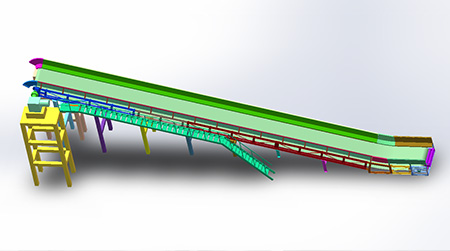

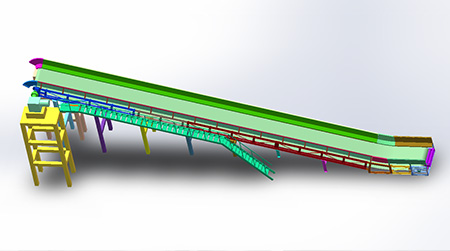

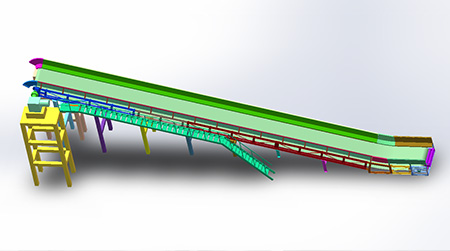

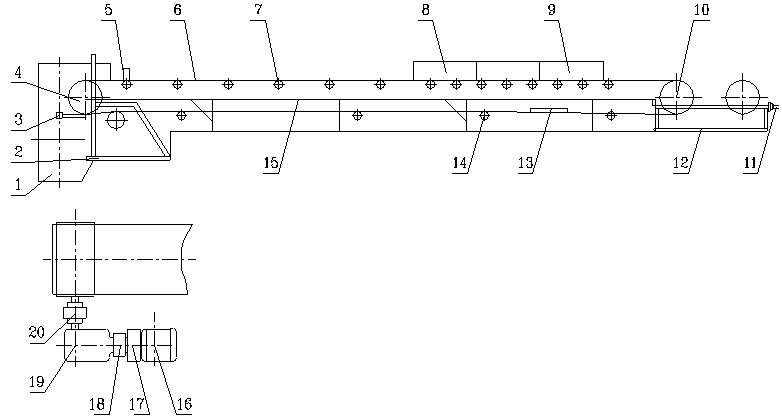

Figure 1 Complete Unit Structure of Belt Conveyor

1. Head hopper 2. Frame 3. Head belt cleaner4. Driving pulley 5. Safety guards 6. Belt 7. Carrying idler 8. Impact idler9. Feed chute 10. Bend pulley 11. Screw take-ups 12. Tail frame13. Belt cleaner14. Return idler15. Intermediate frame16. Motor17. Fluid coupling18. Brake 19.Gear unit 20. Coupling